Sea Stone Pipes

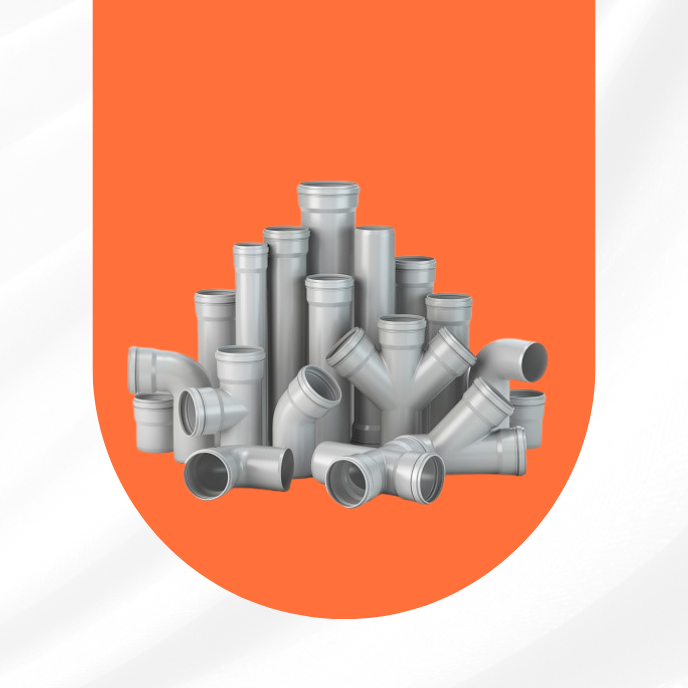

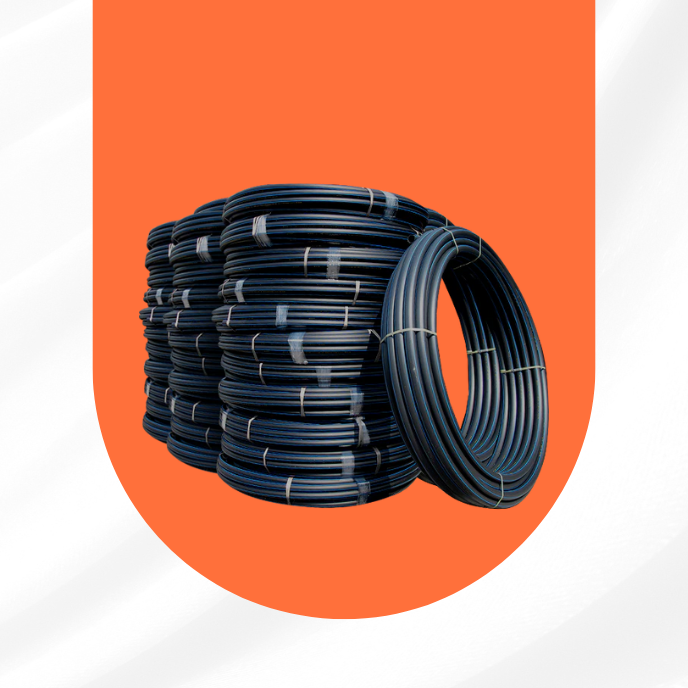

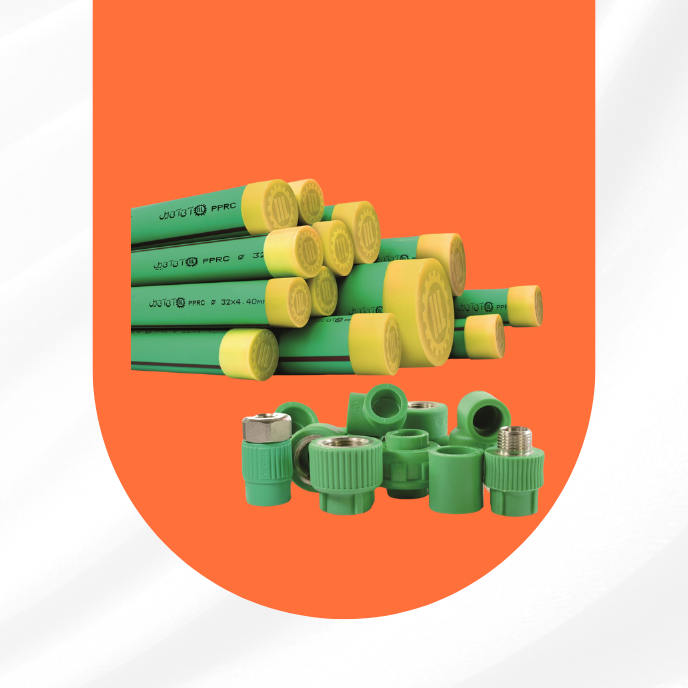

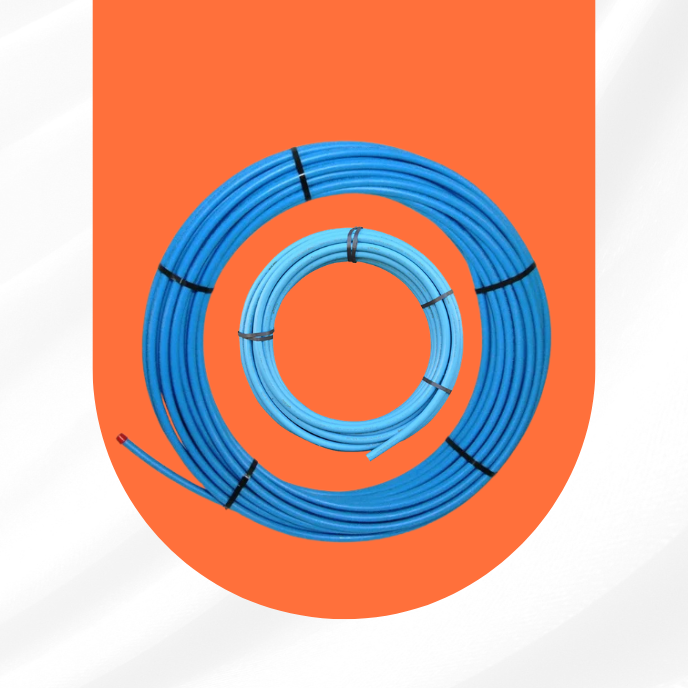

At SPI, we are committed to delivering high-quality PVC, HDPE & PPR pipes and fittings that meet industry standards for durability, strength, and performance.

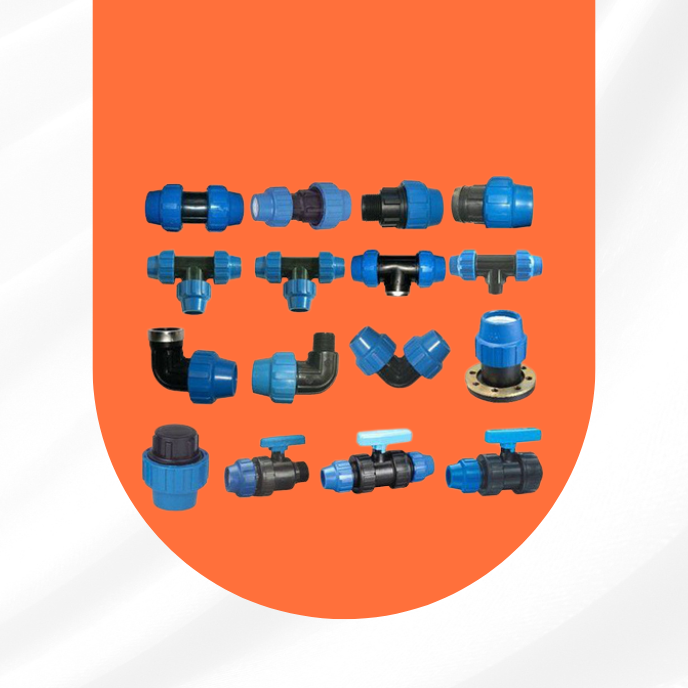

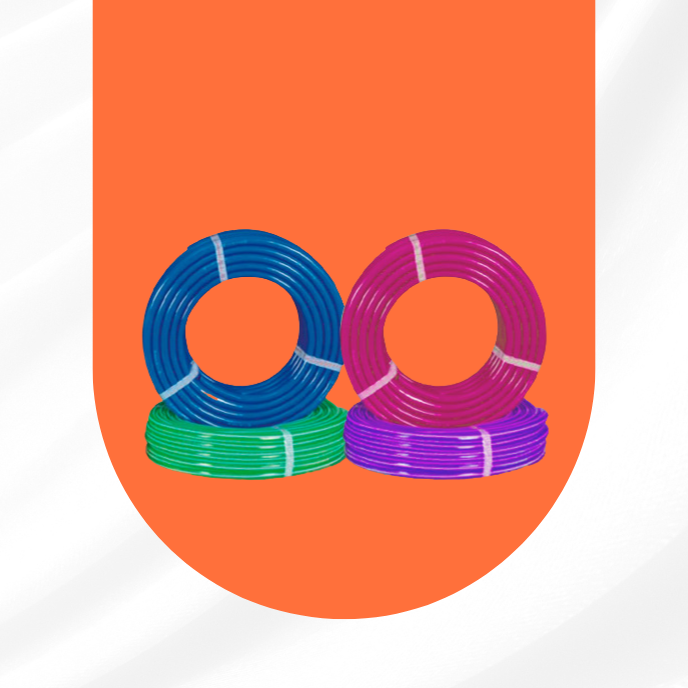

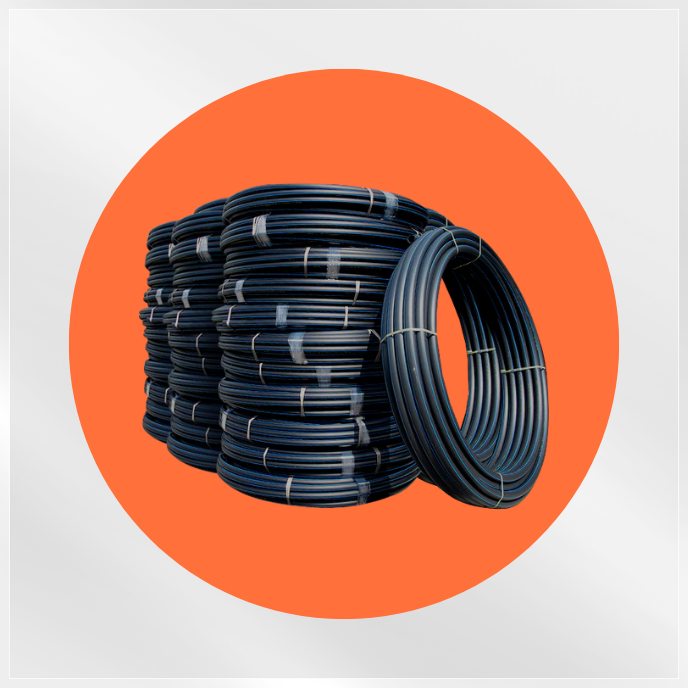

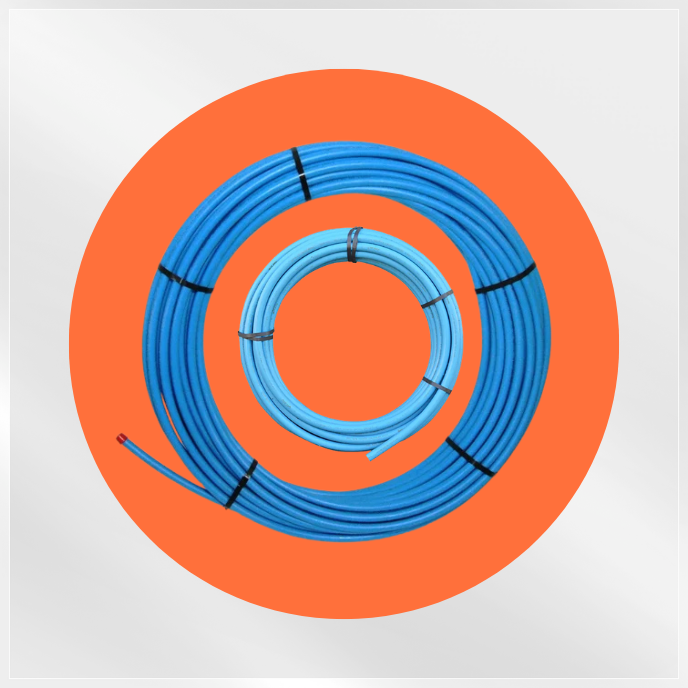

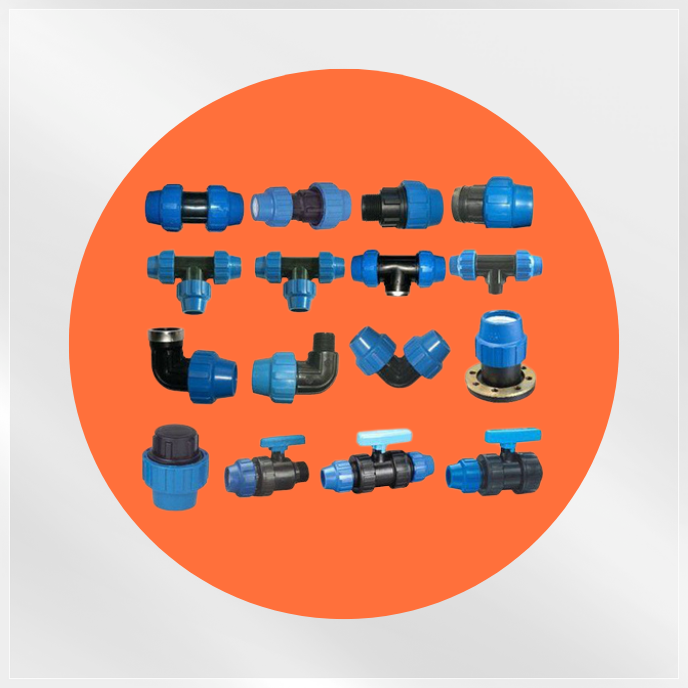

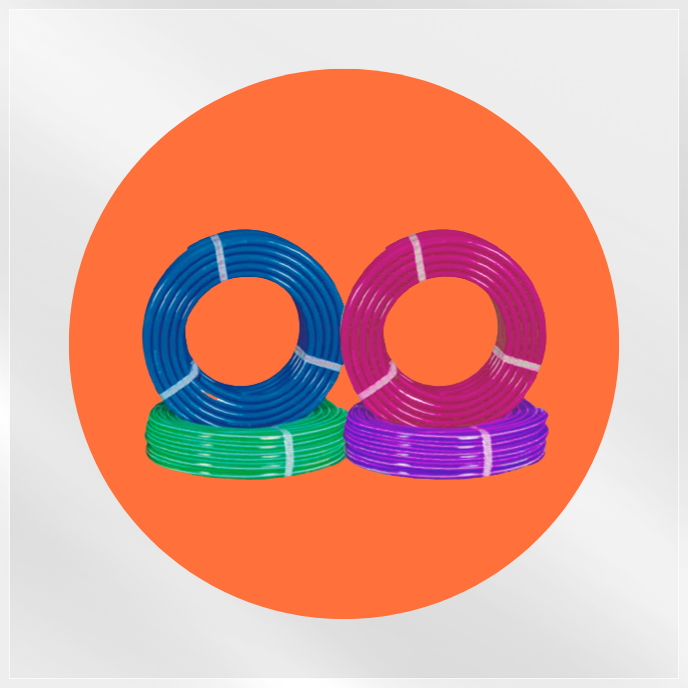

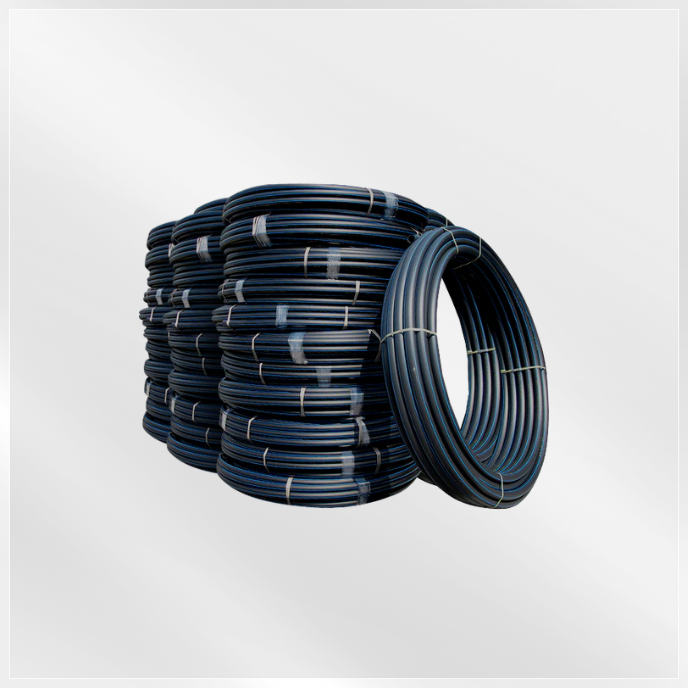

At SPI, we are committed to delivering high-quality PVC, HDPE & PPR pipes and fittings that meet industry standards for durability, strength, and performance. As a leading PVC, HDPE & PPR pipes and fittings manufacturing factory, we specialize in producing a wide range of pipes for residential, commercial, agricultural, and industrial applications.

Worldwide Manufacturing

Best Quality Production

Seastone Pipes Industry

Quality Material

We use only certified, high-grade raw materials to ensure strength, durability, and long-lasting performance across all our piping products.

Advanced Technology

Our facilities are equipped with state-of-the-art machinery to produce precise, consistent, and defect-free pipes and fittings.

Experienced Team

Our skilled engineers and technicians bring years of expertise to deliver innovative, reliable piping systems tailored to your requirements.

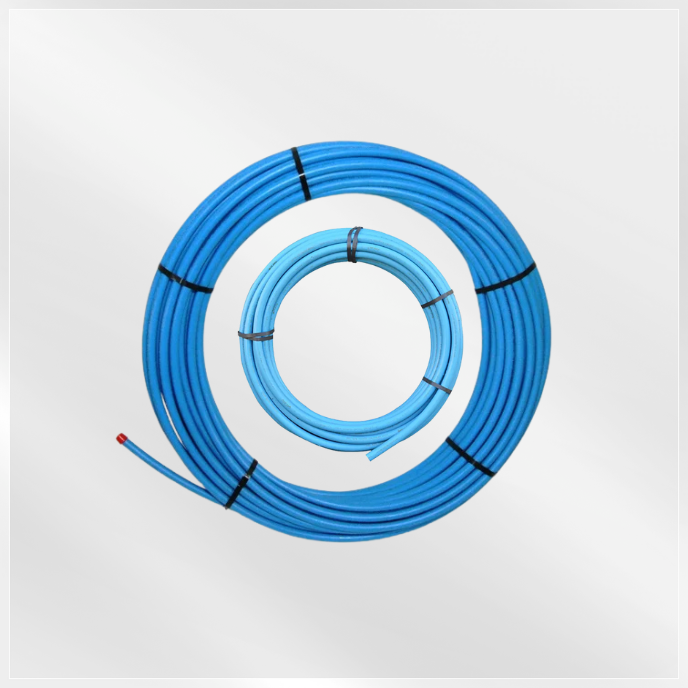

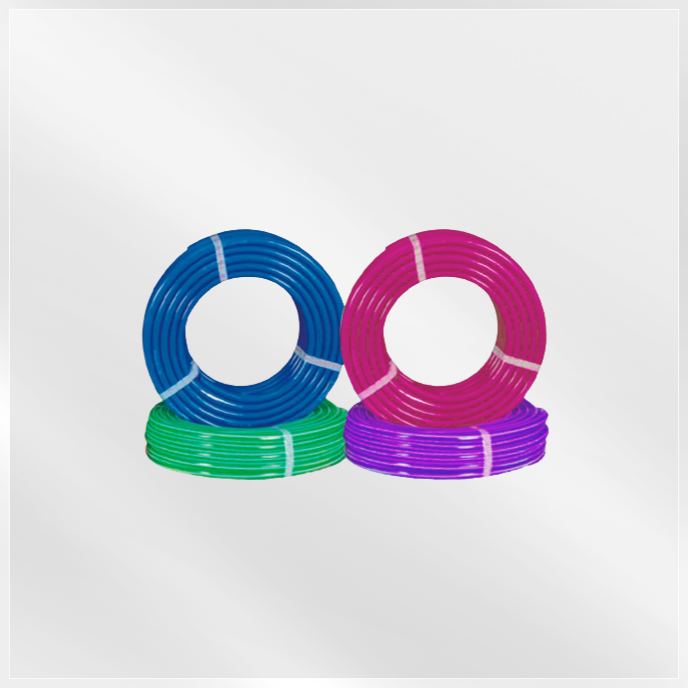

Our Product Portfolio

Our Product Portfolio

Our Product Portfolio

Frequently Asked Questions

Get Every Single Answer From Here

Have questions about our PVC, HDPE & PPR pipes and fitting productions? Our FAQs section provides clear answers to common inquiries.

HDPE Pipes: Highly flexible, durable, and resistant to chemicals and extreme conditions.

PPR Pipes: Best for hot and cold water supply due to their heat resistance.

Our Happy Customers Say About

Suleman Raza

Owais Ahmed

Mian Bahadur